Failure Analysis

Failure analysis is mainly to estimate the failure mode and find out the failure root cause and failure mechanism with the help of various test instruments and analysis methods, so as to help customers put forward suggestions to prevent the failure again.

Ultrahigh Definition Digital Microscope(3D OM)

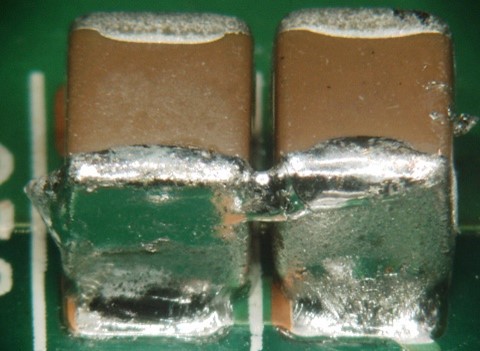

3D OM (3D Optical microscope) has large depth of field and advanced measuring functions to focus on the object under test of different heights at different angles and obtain clear images for observation. 3D OM is suitable for the inspection and failure analysis of electronic part soldering.

Main Application

- Detection of potential PCB defects, such as nodules, weave exposure, glass fiber exposure, solder mask, text ect.

- Detection of potential detects in electronic products, such as poor soldering,solder ball deformation.

- Appearance check and analysis of active and passive components.

- Analysis and measurement of all materials.

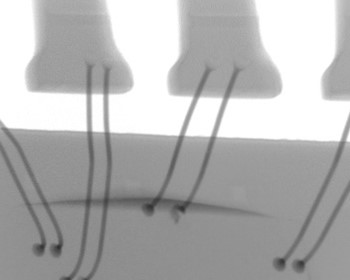

2D X-Ray

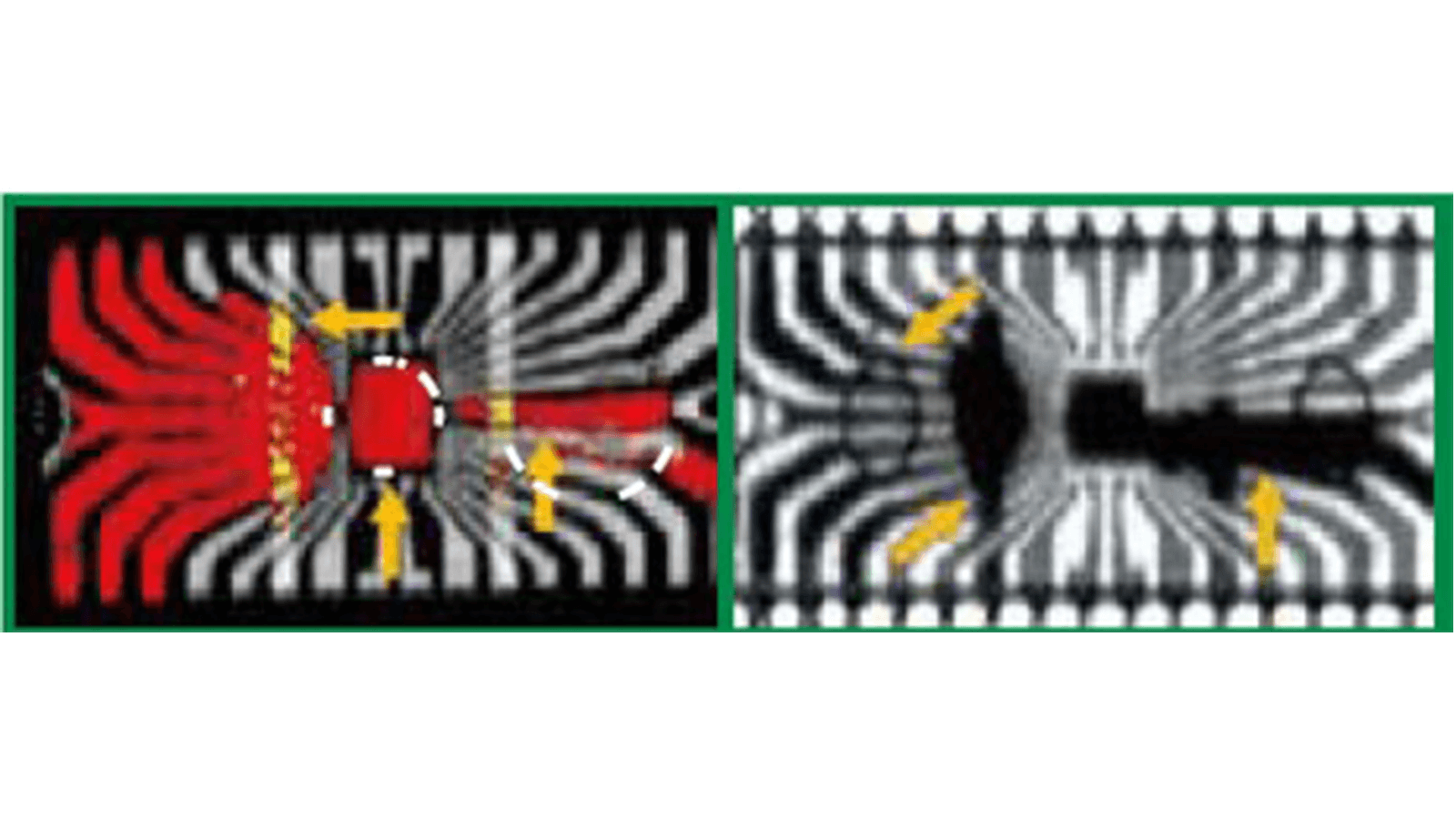

Scanning Acoustic Tomography(SAT)

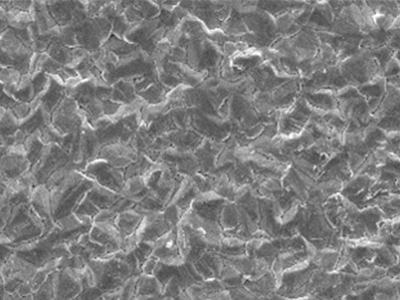

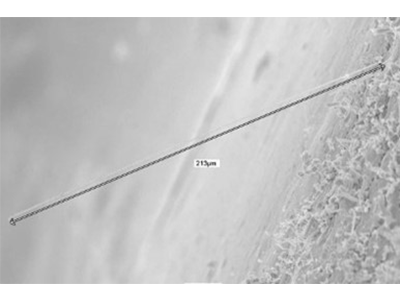

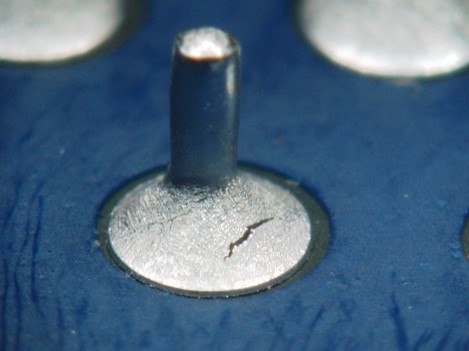

Cross Section Analysis

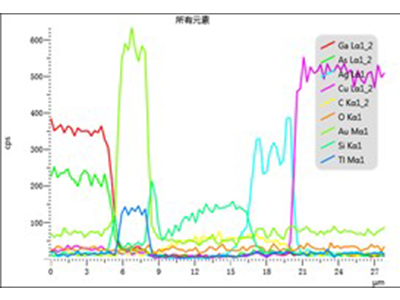

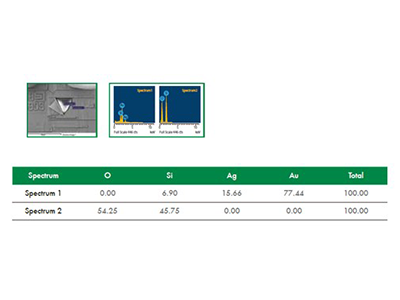

Scanning Electron Microscope & Energy Dispersive Spectrometer (SEM&EDS))